WEENTEK DTF printing transfer film is a crucial component in the WEENTEK DTF printing process. It is a special film that carries the printed design and acts as a medium for transferring the design onto the desired substrate. The transfer film is typically made of a thin plastic material that has adhesive properties.

Here is how the WEENTEK DTF printing transfer film works:

Design Creation: The desired design is created using specific software and then printed onto the WEENTEK DTF transfer film. This design can include various colors, patterns, or graphics.

Adhesive Layer: The transfer film has a layer of adhesive coating on one side. This adhesive layer helps to hold the ink and toner particles during the printing process.

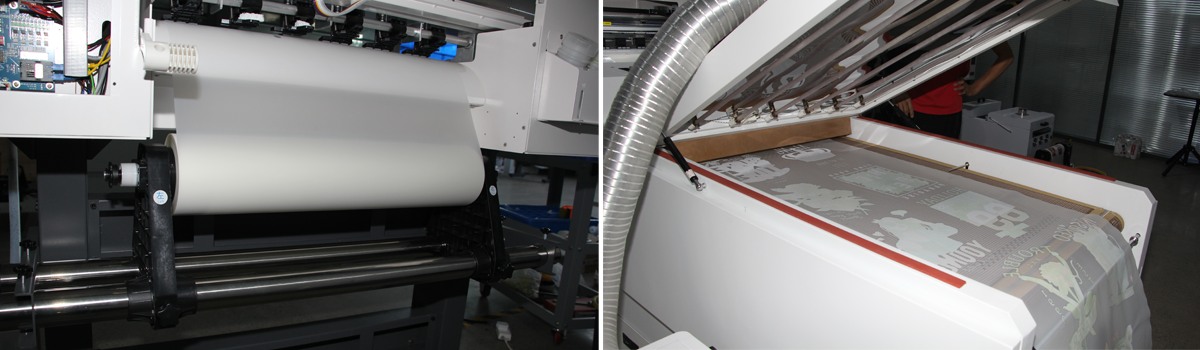

Printing Process: The transfer film is loaded into the WEENTEK DTF printer, which uses heat and pressure to transfer the ink or toner from the film onto the substrate. The printer applies the appropriate temperature and pressure to ensure proper adhesion of the design.

Transfer onto Substrate: Once the design is printed onto the transfer film, it is ready to be transferred onto the desired substrate. The transfer is typically done by applying heat and pressure through a heat press or similar equipment. This process causes the ink or toner particles to transfer from the film onto the substrate, creating the final design.

Film Removal: After the transfer is complete, the transfer film is peeled off, leaving behind the printed design on the substrate. The film can be discarded or reused, depending on the specific type and quality of transfer film used.

WEENTEK DTF printing transfer films are available in different sizes and types to accommodate various printing needs. Some films are specifically designed for textiles, while others can be used for printing on rigid surfaces such as ceramics or glass. It is essential to choose the appropriate transfer film that is compatible with the printer and the intended substrate to ensure optimal print quality and durability.

Overall, the WEENTEK DTF printing transfer film plays a critical role in transferring the design from the film onto the substrate during the WEENTEK DTF printing process. It enables high-quality, vibrant prints and allows for customization on a wide range of materials.

In the fashion industry, WEENTEK DTF printers have revolutionized custom clothing production. They allow for high-quality prints on various fabrics, including cotton, polyester, and even leather. This has opened up new possibilities for designers and clothing brands to create unique and personalized garments.

WEENTEK DTF printers are also widely used in the production of promotional products. Companies can now easily print their logos and designs on items such as t-shirts, tote bags, and caps. This offers a cost-effective and efficient way to create branded merchandise for marketing and promotional purposes.

The manufacturing sector has also benefited from the versatility of WEENTEK DTF printers. They can be used to print labels, tags, and packaging materials with intricate designs and vibrant colors. This helps businesses enhance the visual appeal of their products and differentiate themselves in the market.

Moreover, WEENTEK DTF printing has gained popularity in the DIY (do-it-yourself) community. Hobbyists and creative individuals can now design and print their own unique patterns and designs on various substrates. This has made personalized crafts and home decor more accessible and affordable.

Overall, the widespread application of WEENTEK DTF printers is driven by their ability to produce high-quality prints on a wide range of materials, their ease of use, and their affordability. As technology continues to advance, we can expect further improvements in WEENTEK DTF printing capabilities and increased adoption across industries.