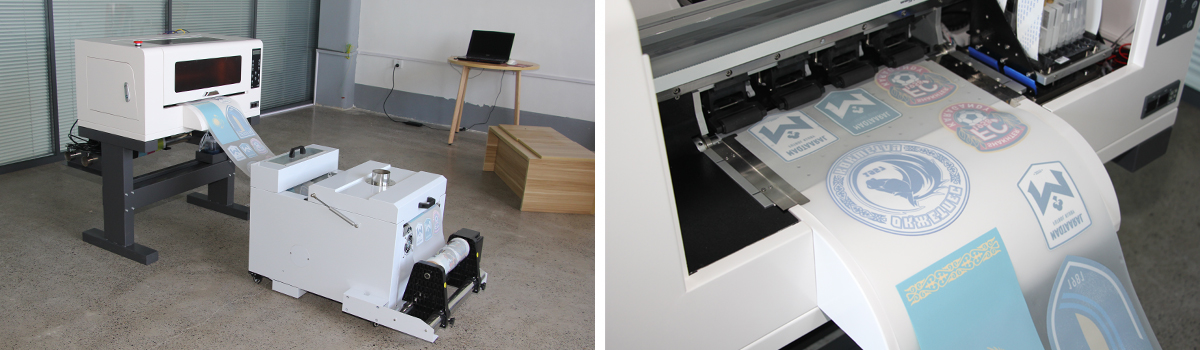

WeenTek WK-300 A3 DTF Printer Equipped with automatic powder shaking machine, which is accurately aligned with printing films, hot melt adhesive powder is sprayed smoothly.

There is no need for engraving, typesetting and lamination, which effectively improves production efficiency.

WeenTek WK-300 A3 DTF Printer can be widely used different kinds of fabrics, leather, bags, shoes and hats, clothing, socks, masks, gloves, umbrellas, plush toys, knitted underwear, swimwear, and other textile and fiber crafts, etc.

1. Design Preparation: The design to be printed is prepared digitally using graphic design software. This can include creating or importing images, adding text, and adjusting colors.

2. Printing Base Layer: A base layer of adhesive is printed onto a transparent film. This layer helps the ink adhere to the final material and prevents smudging.

3. Inkjet Printing: The DTF printer uses inkjet technology to print the design onto the adhesive layer of the film. The printer sprays tiny droplets of ink onto the film, creating the desired pattern or image.

4. Color Layer Printing: Once the base layer is printed, the printer moves on to printing the color layers. Each color is printed separately, and multiple passes may be required to achieve the desired vibrancy and resolution.

5. Film Transfer: After the design is fully printed, the film is carefully placed onto the material to be printed, such as a t-shirt or fabric. The adhesive layer helps bond the ink to the material.

6. Heat Transfer: The material with the film attached is then subjected to heat press machine. The heat and pressure applied activate the adhesive layer, allowing the ink to transfer from the film onto the material. This process ensures a durable and long-lasting print.

7. Finishing: Once the transfer is complete, the film is removed, and the printed material may undergo additional steps like curing or washing to enhance the durability of the print.

High-definition printing resolution, unlimited printing color, bright and beautiful color effect. Bright and beautiful, realistic effect, pattern can be washed without fading and anti-stretch.

Fast printing speed: DTF Printer has a high printing speed, which can greatly reduce the printing time and improve the printing efficiency.

High printing accuracy: dTF Printer has a high printing accuracy, which can ensure the printing quality of the final product.

High material utilization rate: dTF Printer can use a variety of materials for printing, such as plastic, metal, glass, etc., and has a high material utilization rate.

Complex and fine printing: dTF Printer can print complex and fine models, which can meet the needs of various fields such as medical, architecture, aviation and other fields.

WeenTek Digital (https://www.joyin-digital.com) used advanced and practical technology to design and produce A3 DTF Printer, 300mm DTF Printer, 70cm DTF Printer, 700 DTF Printer, PET Film Printer, DTF Printing Machine, Sublimation Printer and other mature products.