The use of Hansen boards in JoyinJet DTF (Direct-to-Film) printing has several important benefits:

Enhanced print quality: Hansen boards provide a stable and flat surface for the printing process, ensuring precise and accurate ink deposition on the film. This helps to maintain sharp details, fine lines, and vibrant colors, resulting in high-quality prints.

Reduction of moiré patterns: Moiré patterns occur when two regular patterns overlap, creating unwanted interference patterns. Hansen boards have a smooth and uniform surface, reducing the likelihood of moiré patterns occurring during the printing process.

Improved ink adhesion: Hansen boards have good ink absorption properties and allow for better adhesion of the ink to the film. This ensures that the ink adheres properly without smudging or smearing, enhancing the overall durability and longevity of the printed design.

Easy handling and alignment: Hansen boards are lightweight, rigid, and easy to handle. They can be easily aligned and secured on the printing bed, providing stability and accuracy during the printing process. This helps to ensure consistent registration and alignment of the film, minimizing errors and wastage.

Longevity and reusability: Hansen boards are durable and can withstand repeated use without warping or deteriorating. They can be cleaned and reused multiple times, making them a cost-effective option in the long run.

In JoyinJet DTF printing, Hansen boards are crucial for achieving high-quality prints. These specialized boards provide a smooth and flat surface for the film to adhere to during the printing process. They help ensure that the ink is transferred accurately and evenly onto the fabric or substrate.

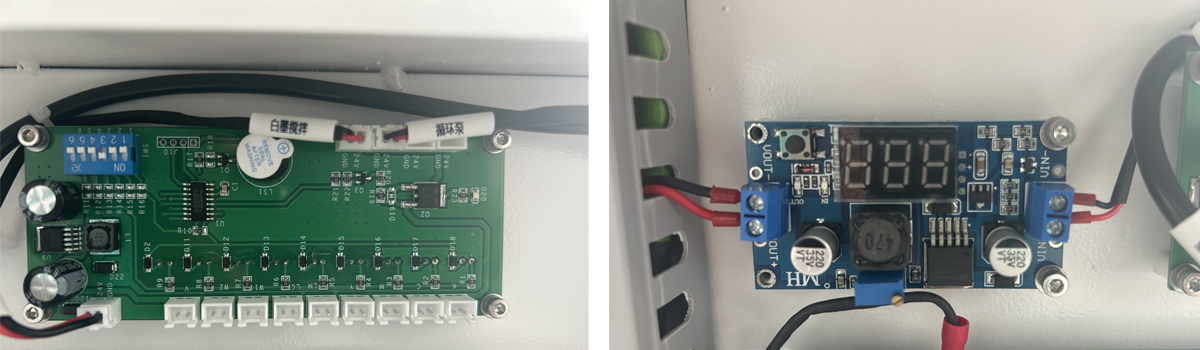

A paper shortage alarm is an essential feature in JoyinJet DTF printer. It is designed to alert the user when the paper supply is running low or has reached a critical level. This alarm helps prevent printing errors or disruptions by allowing the operator to replace or refill the paper in a timely manner. It ensures uninterrupted printing and minimizes wastage of ink and other resources.

White ink circulation and stirring are vital aspects of JoyinJet DTF printing. White ink tends to settle over time, leading to inconsistencies in print quality if not properly circulated and stirred. JoyinJet DTF printers are equipped with mechanisms to agitate the white ink periodically, ensuring its even distribution and maintaining its viscosity. This process helps achieve consistent and vibrant white prints on various fabrics or substrates.

These technical considerations and features play a significant role in ensuring efficient and high-quality JoyinJet DTF printing results. By using Hansen boards, monitoring paper supply, and maintaining proper white ink circulation, printers can optimize their workflow and deliver outstanding prints.