Circulation and stirring of white ink in DTF (Direct to Film) printing are essential for several reasons:

Consistent Ink Distribution: White ink can settle or separate over time, leading to uneven distribution. Stirring ensures that the particles remain evenly suspended, providing consistent color and opacity in prints.

Prevent Clogging: Regular circulation helps prevent the white ink from clogging the printhead. Clogged nozzles can disrupt printing quality and lead to increased maintenance costs.

Improved Print Quality: Proper mixing of the white ink results in a smoother application on the film, which enhances the overall print quality, especially for designs requiring solid white backgrounds.

Better Adhesion: When white ink is properly stirred, it adheres better to the film surface, improving the durability and longevity of the prints once they are transferred onto garments.

Reduced Waste: By ensuring that the white ink is well mixed and used efficiently, you minimize waste and maximize the use of your materials.

Temperature Control: Ink viscosity can change with temperature. Circulating and stirring the white ink can help maintain a consistent temperature throughout the mixture, which is critical for achieving optimal print results.

Avoiding Settling Issues: Over time, pigments in white ink may settle at the bottom of the container. Regular stirring prevents this settling and ensures that the ink remains usable over extended periods without degradation.

Homogeneity for Multi-Layer Prints: In designs that require multiple layers, even mixing of white ink ensures that each layer bonds well with others. This is particularly important for achieving vibrant colors and preventing issues like bleeding or fading.

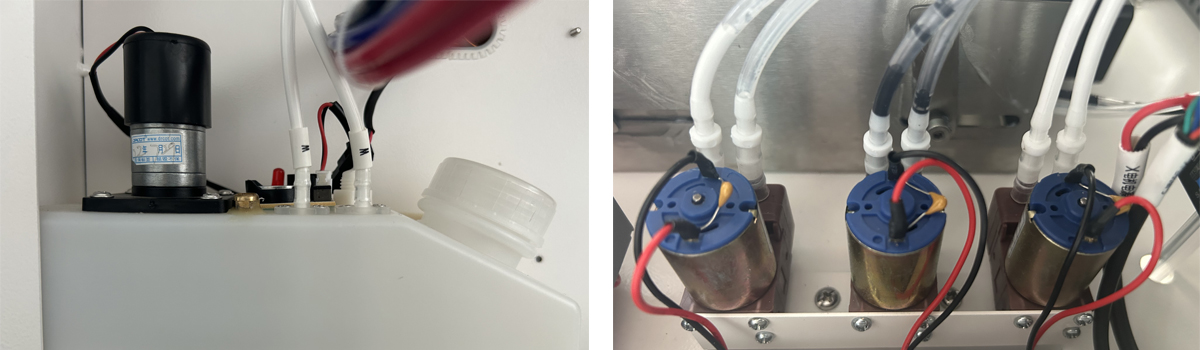

Ease of Use: Automated stirring or circulation systems integrated into the DTF printing process can streamline workflow. Operators spend less time manually mixing inks, allowing for greater efficiency in production.

Quality Control: Consistent stirring and circulation can be part of a quality control process, ensuring that each batch of prints meets desired standards. This reduces the risk of errors due to inconsistent ink quality.

In summary, white ink circulation and stirring are crucial practices in DTF printing that contribute to consistent print quality, operational efficiency, and reduced maintenance issues. Implementing these practices helps in achieving superior printing results and enhances the overall effectiveness of the printing process.