The continuous circulation of white ink in a WEENTEK DTF Printers is necessary to prevent clogging and maintain the ink’s consistency for optimal printing. Here are a few reasons why white ink requires continuous circulation:

Pigment Settlement: White ink contains pigments that may settle or separate over time. Continuous circulation helps prevent the pigments from settling at the bottom of the ink cartridge or printhead, ensuring a consistent color distribution.

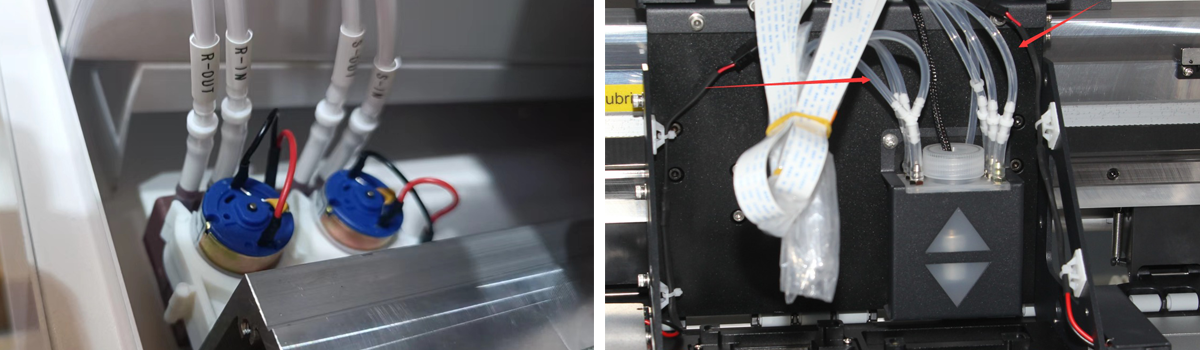

Particle Suspension: White ink often contains larger pigment particles compared to other colored inks. These particles can settle and clog the printhead nozzles if not circulated regularly. Continuous circulation keeps the particles suspended in the ink and prevents blockages.

Printhead Maintenance: The constant circulation of white ink helps in maintaining the printhead’s health. It prevents ink from drying out, reducing the risk of clogs that can affect print quality. It also ensures that ink is readily available when needed.

Ink Consistency: White ink is often thicker and denser than other colored inks. Continuous circulation helps maintain the ink’s viscosity and prevents it from thickening or drying out, ensuring smooth flow through the printhead nozzles. This consistency is crucial for achieving accurate and uniform printing results.

Preventing Clogs: White ink is prone to clogging due to its higher pigment concentration. If the ink sits idle for extended periods without circulation, it can dry and clog the printhead nozzles, affecting print quality and causing costly repairs. Continuous circulation helps prevent ink from settling and clogging the system.

Air Bubble Removal: Air bubbles can form in ink lines or cartridges, especially during periods of inactivity or when changing cartridges. These bubbles can disrupt ink flow and cause inconsistent printing results. Continuous circulation helps remove air bubbles, ensuring a smooth and uninterrupted ink supply.

Printhead Protection: The continuous circulation of white ink helps to keep the printhead nozzles hydrated and prevent them from drying out. Dry nozzles can lead to blockages and affect ink flow, resulting in poor print quality. By maintaining constant ink circulation, the printhead is protected, prolonging its lifespan and performance.

In summary, continuous circulation of white ink in WEENTEK DTF Printers is essential to ensure consistent ink flow, prevent clogs, maintain color accuracy, and protect the printhead. It helps to address the specific characteristics of white ink, such as settling pigments, larger particles, and higher viscosity. By implementing continuous circulation systems or regular manual circulation, WEENTEK DTF Printers can achieve better print quality and reliability when using white ink.