The continuous circulation of white ink in a JoyinJet DTF Printers is necessary to prevent clogging and maintain the ink’s consistency for optimal printing. Here are a few reasons why white ink requires continuous circulation:

Pigment settling: The white ink used in JoyinJet DTF printing contains pigments that may settle over time, leading to inconsistent color distribution and print quality. Circulation and stirring help to prevent this settling by keeping the pigment particles evenly dispersed in the ink.

Ink consistency: Regular circulation and stirring ensure that the white ink maintains its viscosity and consistency throughout the printing process. This is important for achieving accurate and consistent color output on various materials.

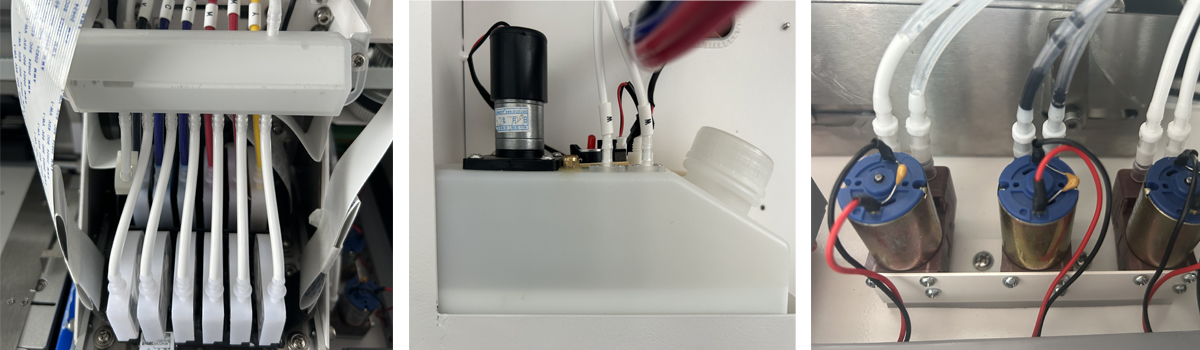

Prevent clogging: White ink has a higher viscosity compared to other colors, which makes it more prone to clogging the printer’s ink lines, printheads, or nozzles. Circulation and stirring help prevent the ink from drying out or forming clumps, reducing the chances of clogs and improving printer performance.

Color accuracy: DTF printers often use multiple layers of ink to achieve vibrant and opaque prints, especially when printing on dark or colored fabrics. By ensuring proper circulation and stirring of the white ink, the printer can deliver consistent and uniform coverage, resulting in accurate color representation.

Ink separation: Over time, the components in the white ink can separate, resulting in a non-homogeneous mixture. Circulation and stirring help to recombine these components and maintain the ink’s integrity, ensuring consistent printing results.

Print head maintenance: Proper circulation and stirring of white ink help to prevent the ink from drying or coagulating within the print heads. This is crucial for preventing blockages and maintaining the longevity of the print heads.

Ink efficiency: White ink often requires more ink coverage on a substrate compared to other colors. Circulation and stirring help to ensure that the ink is used efficiently, reducing waste and optimizing the printing process.

Consistent color matching: In DTF printing, accurate color matching is essential, particularly when reproducing specific brand colors or logos. Through regular circulation and stirring, the white ink’s color and consistency can be monitored and adjusted if needed, ensuring consistent results across different print runs.

Improved print quality: By maintaining proper white ink circulation and stirring, DTF printers can produce prints with sharper details, smooth gradients, and vibrant colors. This is crucial for achieving professional-quality output that meets the expectations of customers.

In summary, regular circulation and stirring of white ink in JoyinJet DTF printers help maintain ink consistency, prevent clogs, ensure efficient ink usage, and improve print quality and color accuracy. These practices are essential for achieving optimal results in DTF printing processes.